Product Description

Product Description

Standard and various, ratio 1:1,1.5:1,2:1,3:1, all are exact ratio.

When the ratio is not 1:1 and pinion shaft is input, so cross shaft is reduced output. When cross shaft

is input, the pinion shaft is increased output.

Spiral bevel gear, stable transmission, low noise level, small vibration and strong loading capacity.

Double input shaft is available.

Multiple output shaft is available.

Any mounting position is available.

Main applied for

Agriculture and food

Building and construction

Forest and paper

Metal processing

Chemical industry and environmental protection

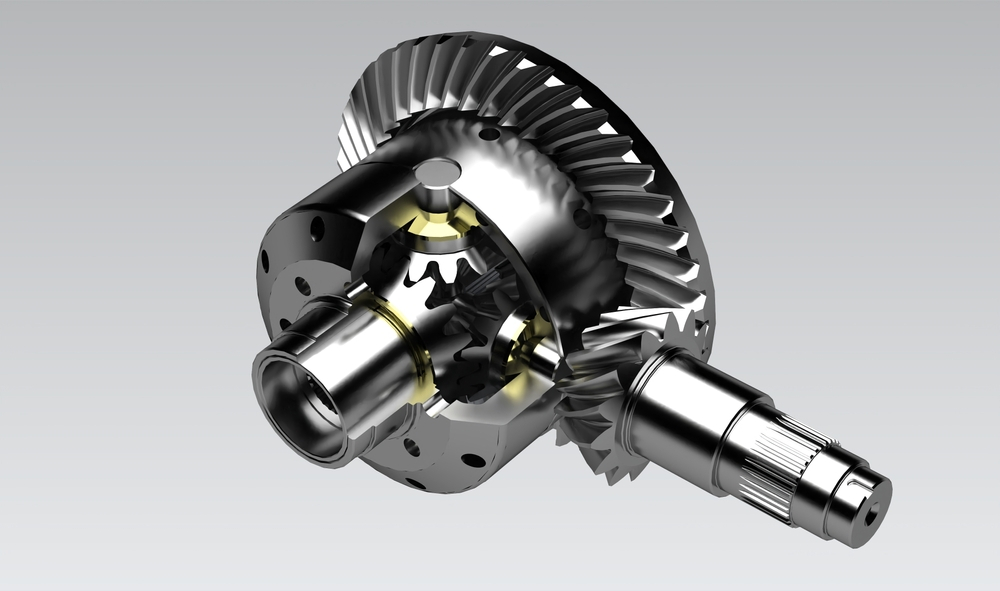

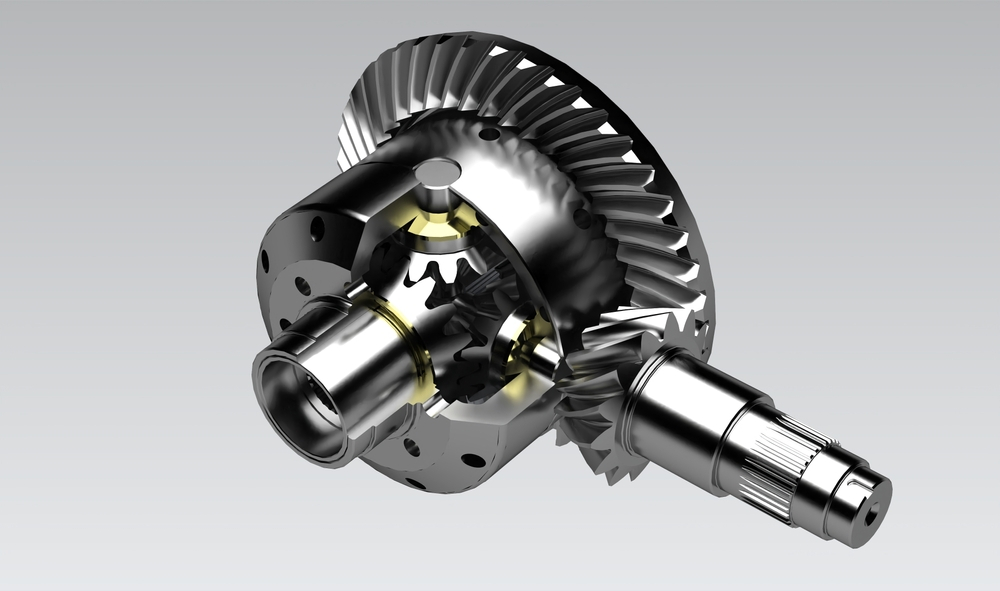

Detailed Photos

Product Parameters

|

Housing material |

Cast iron/Ductile iron |

|

Housing hardness |

HBS190-240 |

|

Gear material |

20CrMnTi alloy steel |

|

Surface hardness of gears |

HRC58~62 |

|

Gear core hardness |

HRC33~40 |

|

Input / Output shaft material |

42CrMo alloy steel |

|

Input / Output shaft hardness |

HRC25~30 |

|

Machining precision of gears |

Accurate grinding, 6~5 Grade |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat treatment |

tempering, cementiting, quenching, etc. |

|

Efficiency |

98% |

|

Noise (MAX) |

60~68dB |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Brand of bearings |

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK. |

|

Brand of oil seal |

CHINAMFG — ZheJiang or other brands requested |

Our Advantages

Packaging & Shipping

Company Profile

Xihu (West Lake) Dis.ng Transmission Equipment Co., Ltd. located HangZhou city, ZHangZhoug, as 1 professional

manufacturer and exporter of cycloidal pin wheel reducer,worm reducer, gear reducer, gearbox ,

AC motor and relative spare parts, owns rich experience in this line for many years.

We are 1 direct factory, with advanced production equipment, the strong development team and

producing capacity to offer quality products for customers.

Our products widely served to various industries of Metallurgy, Chemicals, textile,medicine,wooden

etc. Main markets: China, Africa,Australia,Vietnam, Turkey,Japan, Korea, Philippines…

Welcome to ask us any questions, good offer always for you for long term business.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.

Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q:How to choose a gearbox which meets your requirement?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

How do differential gears handle varying speeds in a vehicle’s wheels?

A differential gear system is designed to handle varying speeds in a vehicle’s wheels, allowing them to rotate at different rates while maintaining torque distribution. Here’s a detailed explanation of how differential gears achieve this:

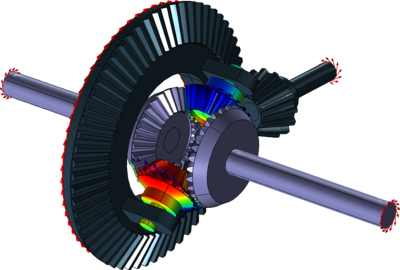

1. Differential Assembly:

The differential assembly consists of several gears, including the ring and pinion gears, side gears, and spider gears. These components work together to accommodate varying speeds between the wheels.

2. Power Input:

The power is delivered to the differential gears through the driveshaft or transmission. The ring gear receives this power from the driveshaft, while the pinion gear is connected to the ring gear and transfers the rotational force to the differential assembly.

3. Speed Differences:

When a vehicle is moving in a straight line, the wheels ideally rotate at the same speed. However, during turns or when encountering different traction conditions, the wheels need to rotate at varying speeds. This is because the wheel on the outside of a turn covers a greater distance than the inside wheel, resulting in a speed differential.

4. Spider Gears:

The differential gears utilize spider gears, which are small gears located between the side gears. Spider gears allow the side gears to rotate independently of each other, accommodating the speed differences between the wheels.

5. Torque Distribution:

As the spider gears allow the side gears to rotate independently, torque is distributed between the wheels based on their speed differences. The wheel with less resistance or greater traction receives more torque, while the wheel with more resistance or lower traction receives less torque.

6. Smooth Cornering:

During turns, the inside wheel needs to rotate at a slower speed than the outside wheel. The differential gears allow this speed differentiation, enabling smooth cornering without wheel hop or tire scrubbing. By distributing torque appropriately, the differential gears ensure that both wheels receive sufficient power for optimal traction and control.

7. Limited-Slip and Locking Differentials:

In certain differential systems, such as limited-slip differentials or locking differentials, additional mechanisms are employed to further regulate speed differences and torque distribution. Limited-slip differentials use clutch packs or friction plates to provide a predetermined amount of resistance, allowing some differentiation between the wheels while still transferring power. Locking differentials lock the side gears together, ensuring equal torque distribution to both wheels, regardless of traction conditions.

8. Differential Types:

There are different types of differentials, including open differentials, limited-slip differentials, electronic differentials, torque vectoring differentials, and more. Each type utilizes specific technologies and mechanisms to handle varying speeds and torque distribution based on the vehicle’s requirements and driving conditions.

In summary, differential gears handle varying speeds in a vehicle’s wheels by utilizing a system of gears, including spider gears, side gears, ring and pinion gears. The speed differences between the wheels are accommodated by allowing independent rotation of the side gears through the spider gears. Torque distribution is adjusted to ensure optimal traction and control during turns and varying traction conditions. Additional mechanisms, such as limited-slip or locking differentials, can further regulate speed differences and torque distribution for enhanced performance and stability.

What is the role of a center differential in all-wheel-drive systems?

In an all-wheel-drive (AWD) system, the center differential plays a crucial role in distributing power between the front and rear wheels. It is responsible for managing torque transfer and ensuring optimal traction and stability in various driving conditions. Here’s a detailed explanation of the role of a center differential in all-wheel-drive systems:

- Torque Distribution: The center differential’s primary function is to distribute torque between the front and rear axles in an AWD system. It receives power from the engine and transmits it to both the front and rear wheels. The distribution of torque can vary depending on the design and capabilities of the center differential.

- Power Split: The center differential splits the engine’s power between the front and rear axles in a manner that optimizes traction and stability. Under normal driving conditions, it typically distributes torque evenly, providing balanced power to all wheels. This balanced power distribution helps enhance vehicle control and stability.

- Variable Torque Split: In some AWD systems, the center differential can vary the torque split based on driving conditions. It can adjust the distribution of power between the front and rear axles to optimize traction and handling. For example, if the system detects slippage in the front wheels, it can transfer more torque to the rear wheels to improve traction and maintain vehicle stability.

- Traction Enhancement: The center differential helps improve traction by allowing the front and rear wheels to rotate at different speeds. This capability is particularly beneficial in situations where the left and right wheels on the same axle encounter varying levels of grip, such as when driving on slippery or uneven surfaces. By allowing the wheels to rotate at different speeds, the center differential enables the wheels with better traction to receive more power, enhancing overall grip and traction.

- Adaptability to Different Conditions: A well-designed center differential enables an AWD system to adapt to different driving conditions. Whether it’s driving on dry pavement, wet roads, icy surfaces, or off-road terrain, the center differential helps optimize power distribution to maintain traction and stability. It allows the AWD system to provide enhanced grip and control, regardless of the prevailing driving conditions.

- Integration with Other Systems: The center differential often works in conjunction with other vehicle systems to further enhance performance and safety. For example, some AWD systems incorporate electronic controls that can interact with the vehicle’s stability control system, traction control system, or other safety features. This integration helps optimize power delivery, traction management, and overall vehicle dynamics.

In summary, the center differential plays a critical role in all-wheel-drive systems. It distributes torque between the front and rear axles, enhances traction and stability, adapts to different driving conditions, and integrates with other vehicle systems. By effectively managing torque transfer, the center differential helps maximize grip, improve handling, and enhance overall performance in AWD vehicles.

What is the purpose of using a differential gear in an automobile?

A differential gear serves a crucial purpose in an automobile. Here’s a detailed explanation:

The purpose of using a differential gear in an automobile is to allow the wheels to rotate at different speeds while receiving power from the engine. It enables smooth and controlled maneuvering, optimizes traction, and enhances overall performance. The differential gear plays several key roles in an automobile:

1. Torque Distribution:

One of the primary purposes of a differential gear is to distribute torque (rotational force) from the engine to the wheels. As the engine generates power, the differential ensures that it is transmitted to the wheels efficiently and effectively. By dividing the torque between the two wheels, the differential enables both wheels to receive power and propel the automobile forward.

2. Differential Action:

The differential gear allows the wheels to rotate at different speeds when the automobile is turning or when one wheel encounters different traction conditions. This differential action is crucial for smooth and controlled maneuvering. By enabling the outer wheel to rotate faster than the inner wheel during a turn, the differential allows the automobile to negotiate corners without binding or skidding.

3. Wheel Speed Compensation:

When the automobile is turning, the inside wheel travels a shorter distance compared to the outside wheel. Without a differential gear, this speed difference would cause significant drivetrain stress and tire wear. The differential gear compensates for the varying wheel speeds by allowing the wheels to rotate at different speeds, ensuring smooth operation and minimizing strain on the drivetrain components.

4. Traction Improvement:

In situations where one wheel loses traction, such as when driving on slippery surfaces or uneven terrain, the differential gear helps improve traction. By allowing the wheel with traction to receive more power, the differential ensures that the automobile can continue moving forward. This is particularly important in automobiles with two-wheel drive, as the differential helps optimize power delivery to the wheel with better traction.

5. Reducing Tire Wear:

The differential gear contributes to reducing tire wear by accommodating differences in wheel speeds. By allowing the wheels to rotate at different speeds during turns, the differential minimizes tire scrubbing and uneven wear. It helps distribute the forces evenly across the tires, promoting longer tire life and maintaining better overall traction.

6. Enhanced Stability and Handling:

The differential gear plays a crucial role in enhancing automobile stability and handling. By allowing the wheels to rotate independently, the differential facilitates better control during turns and maneuvering. It helps maintain proper weight distribution, prevents excessive understeer or oversteer, and promotes balanced handling characteristics.

Overall, the purpose of using a differential gear in an automobile is to enable torque distribution, facilitate smooth and controlled maneuvering, optimize traction, reduce tire wear, and enhance stability and handling. The differential gear ensures that power is efficiently delivered to the wheels while accommodating varying speed and traction conditions, resulting in improved performance and driving dynamics.

editor by Dream 2024-05-09